Optimizing Material Handling for Better Throughput

Material Handling Optimization

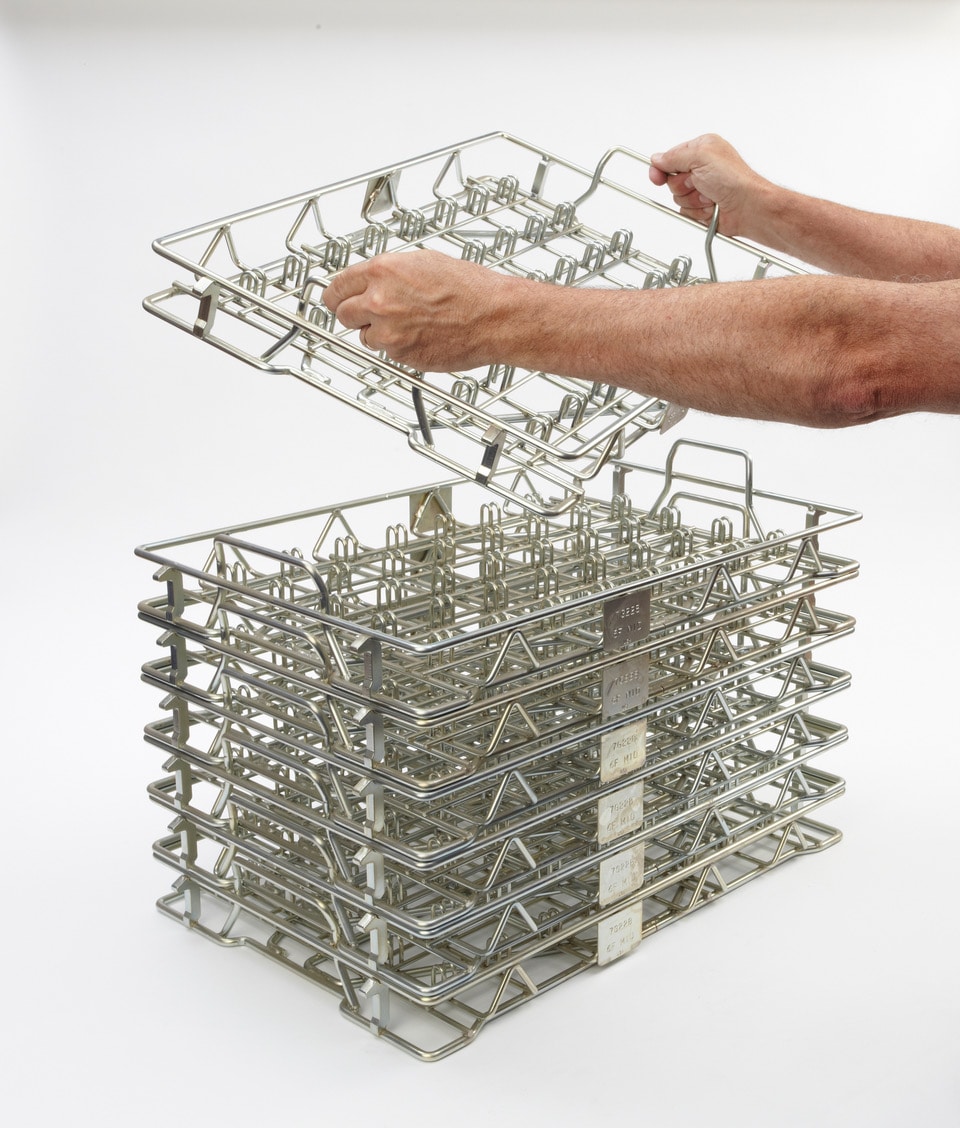

Wire baskets, trays, and carriers are used for a variety of applications from work holding to heat treating to cleaning operations. Wire baskets are used in many applications because they are strong, yet lightweight. The open construction of wire baskets allows air circulation, greater visibility of the product, greater accessibility of the product and allows better run off of cleaning solutions during washing or degreasing operations.

The rounded, smooth surface of the wire can allow parts to be guided into chambers or cells without fracturing or nicking fragile components, whether it is a machined metal component for medical, automotive or military applications or a film protecting food products or pharmaceutical preparations. Wire containers are strong and can easily withstand the wear and tear of factory use. Tooling and fabrication costs for wire baskets can be more economical than baskets made of other materials. Metal baskets are better for the environment because when the baskets are no longer needed (due to a change in product or process) the metal can be recycled to be made into reprocessed metal to keep obsolete material out of landfills.

Material handling can become an issue that does not usually arise unless components are being handled improperly. The improper handling often causes parts to become damaged and may contribute to more scrap and lower productivity (due to rework or increased inspection) in certain assembly areas. If parts are not processed efficiently or moved to the next station quickly enough, throughput can be impacted and cause downtime in downstream operations.

Proper material handling techniques can decrease the indirect cost of manufacturing by reducing the number of times a part must be handled and decrease the loss or damage due to mishandling. Many handling baskets also double as storage bins. If parts are not stored properly, damage may occur. Baskets can be designed with a stacking feature which reduces the amount of floor space required for goods in process.

Material Processing

A related issue in material handling is material processing. Material processing can be heat treating, degreasing, washing or sterilizing. The need for adequate material processing containers becomes apparent when parts cannot be processed quickly enough due to improper design, or insufficient capacity. Many components have to be oriented in a certain way to ensure consistent cleaning and drainage or plating coverage or heat treating uniformity. Acme Wire Products can work with your processing engineers to help develop a processing rack or basket that meets your needs.

The more sophisticated or complex the component, the more engineered the container becomes. A component which must go through several machining or fabricating operations already has a significant labor cost already applied to it before it reaches its final state. In this instance, the manufacturer does not want the operators to carelessly put parts into a box and send them onto the next station. A custom basket or rack for handling these items can prevent damage due to mishandling.

For cleaning and sterilizing operations, 300 series stainless steel, either 304 or 316/316L is typically used as the baskets are going into a wet, high-temperature environment. For most handling baskets, zinc plated steel is the preferred material. For new basket applications, Acme Wire Products’ engineers will consult with the customer and consider the weight of the product the basket will hold, how many parts need to be processed per batch, the part orientation and numerous other factors.

A pin-style basket is typically used to hold parts with a small internal diameter. Larger parts that can be located on the outer surface will often be held in a grid style orientation. Sometimes parts are oriented between rails or on rings. Proper part placement and dimensional accuracy become critical when parts are being loaded or unloaded in automated cells.

Capabilities

Acme Wire Products Co., Inc. of Mystic, CT specializes in designing and fabricating custom wire and metal material handling and processing baskets. As a full-service metal fabricator, Acme can utilize materials in addition to and in conjunction with wire, depending upon a customers’ requirement. Sheet metal, perforated stock, stampings or tubing are all materials that can be combined with wire to obtain the maximum effectiveness in solving our customer’s handling needs.

Acme Wire Products has designed, recommended and manufactured custom handling and processing baskets for customers in many diverse markets. We offer the benefit of our almost 50 years’ experience in the manufacture of carriers for hardware, medical, firearms, pharmaceutical, automotive, optical and food processing industries. Wire carriers can hold parts as delicate as a glass lens or vial or an egg or an electronic component or as sturdy as a gear or a casting.

Often, when a customer is installing a new sterilizing or degreasing line, they will request custom wire baskets to fit their new equipment. Acme Wire’s designers will work with the customer to establish a carrier that will afford the greatest effectiveness and coordinate manufacturing with the installation of their new equipment. Acme Wire also builds baskets, racks, and carriers as components to commercial washing and sterilization equipment.

The design of wire baskets and most wire fabrication is limited only by one’s imagination (and the limitations of technology). There are almost as many types of baskets as there are different parts to be contained. Contact Acme Wire Products to assist you in determining the design which is best suited your handling and processing requirements as well as fabricating the carriers to your specifications! Call Acme Wire Products at 1-800-723-7015 for your production basket requirements!

Acme Wire Products Co., Inc. – Mystic, CT

https://www.acmewire.com

860-572-0511

Fax – 860-572-9456