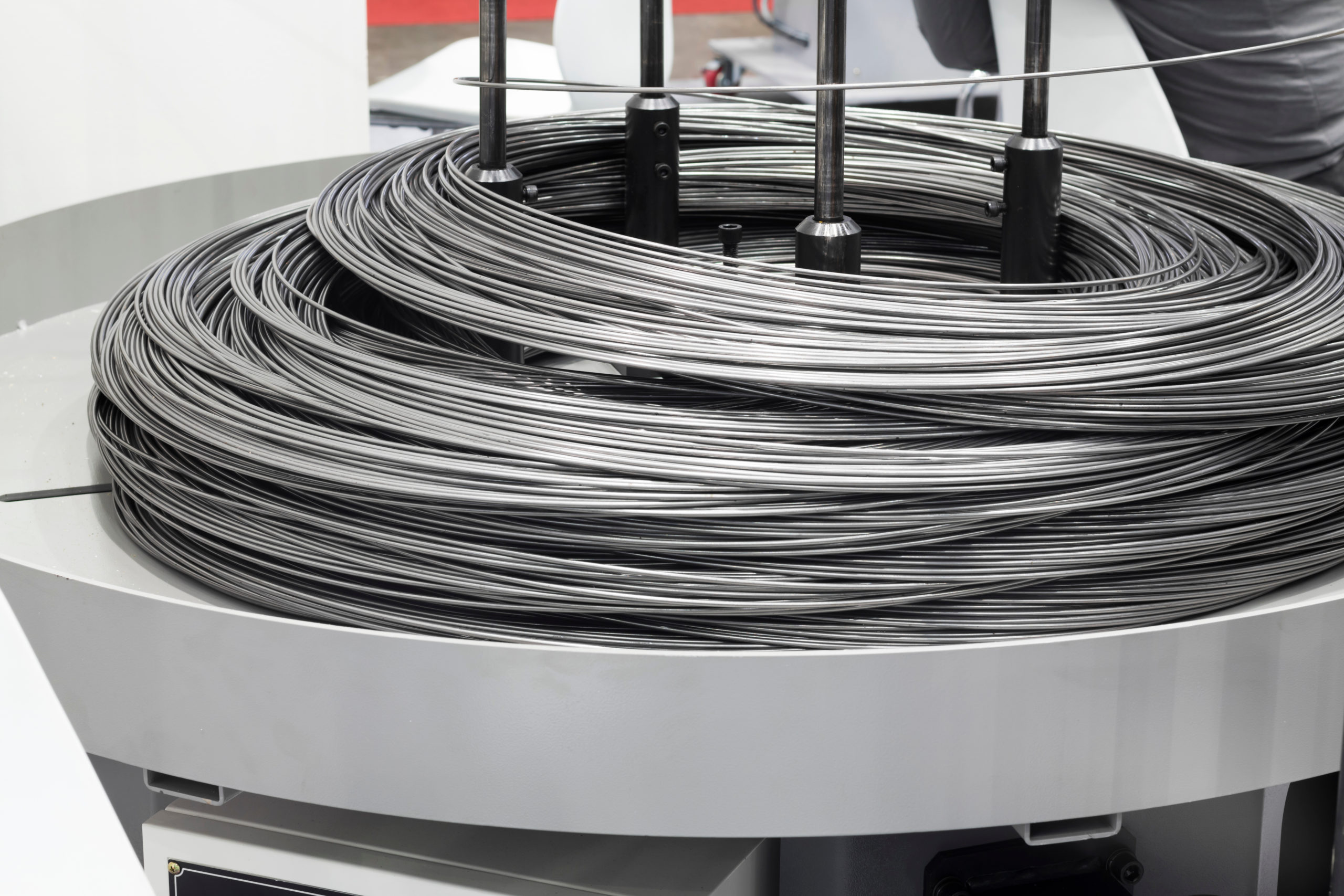

Wire forming is a method for applying force to change the contour of wire by bending, swaging, piercing, chamfering, shearing, or other techniques. The various techniques for wire forming can produce any type of shape, form, or configuration. The process starts with coiled wire that is straightened before being formed.

Common metals used for wire forming include steel, brass, stainless steel, copper, aluminum, and a variety of different alloys. The diameters of wires vary from 0.5 mm to 6.5 mm, or 1/64th of an inch to a quarter inch and can produce 2 and 3 dimensional wire forms.

The types of equipment to complete wire forming vary between manual crafting to advanced CNC programmable machines. The process includes options for coating and protecting final products for use in harsh conditions.

Methods Used for Wire Forming

Though there are several types of equipment used to perform wire forming, in most cases, wire forming machines are manually or automatically operated. Manual machines include ones that are operated by manual force and ones that are electronic but manually loaded. Automatic machines have advanced computer numerically controlled (CNC) programming and complete production without manual involvement.

Methods For Wire Forming

Wire forming is performed using several different processes each designed to achieve a different shape, pattern, or configuration. The methods of wire forming are used for other part production but have been adjusted for wire forming.

Manual Wire Forming:

The oldest method for wire forming is manually operated machines, which involves a hand lever and spindle. Manual machines can be drawn or rotary die and have gears that increase the applied bending force.

Coil Wire Forming:

Coil, or spring wire forming, involves winding wire around a metal blank. It is also used for the manufacture of electrical coils where a conductive wire is evenly wound around a ferromagnetic core. Coil winding takes different forms depending on the final product. Electrical coils have to be more precisely wound than springs and can require more than one winding.

Roll Wire Forming:

Roll forming is a cost efficient method for the production of flat, round, and other shapes of wire parts. The process can manufacture undercuts, knurls, pointing, chamfers, grooves, surface finishes, collars, and threads. Roll formed wire parts have extra strength after being hardened, having rounded edges, and being prefinishing.

Bend Wire Forming:

In the wire bending process, wire can be shaped into unlimited configurations to fit any application. Diameters of 0.4 mm to 16 mm, or 0.016 in to 0.625 in, can be easily formed. Since the bend in the wire is made prior to the wire being cut, the process has no scrap or waste and does not need secondary finishing.

CNC Wire Bending:

CNC wire bending machines can be pneumatic or hydraulic for efficient and rapid production. They can bend and shape rebar to 180o using single or double wire. The machine straightens the bar prior to the bending process. CNC machines have exceptional accuracy and cut wire to the exact required dimensions. The types of wire a CNC machine can be programmed to shape includes music, hard drawn, basic or coated metals, 300 series stainless steel, brass, and beryllium copper. Wire diameters vary between 0.008 in to 0.250 in or 0.0203 mm to 6.35 mm.

CONTACT ACME WIRE PRODUCTS

Acme Wire Products has designed, recommended and manufactured custom wire components for customers in many diverse markets. We offer the benefit of our almost 50 years’ experience in the manufacture of component parts for hardware, medical & lab equipment, cable management, sporting goods, firearms, furniture, guarding, HVAC, pharmaceutical, automotive, optical and food service and processing industries.

Acme Wire’s designers work with our customers to create a wire component that will provide the greatest functional value. The design of wire products such as levers, handles, supports, rings, guards, baskets, trays, grids, frames, shelves are limited only by one’s imagination (and the limitations of technology).

Contact Acme Wire Products to assist you in determining the wire product best suited to your requirements! Call Acme Wire Products at 1-800-723-7015 to get started.

Acme Wire Products Co., Inc. – Mystic, CT

Fax – 860-572-9456