Brass:

Brass is an alloy composed of 67% copper and 33% zinc with the characteristics of copper including its electrical and heat conductivity as well as its malleability. Since it is stronger than copper, it is used in a wider variety of applications, which include wire forming. Some forms of brass have antimony, arsenic, iron, and tin, which are added to improve its mechanical and physical properties, such as hardness, formability, strength or appearance.

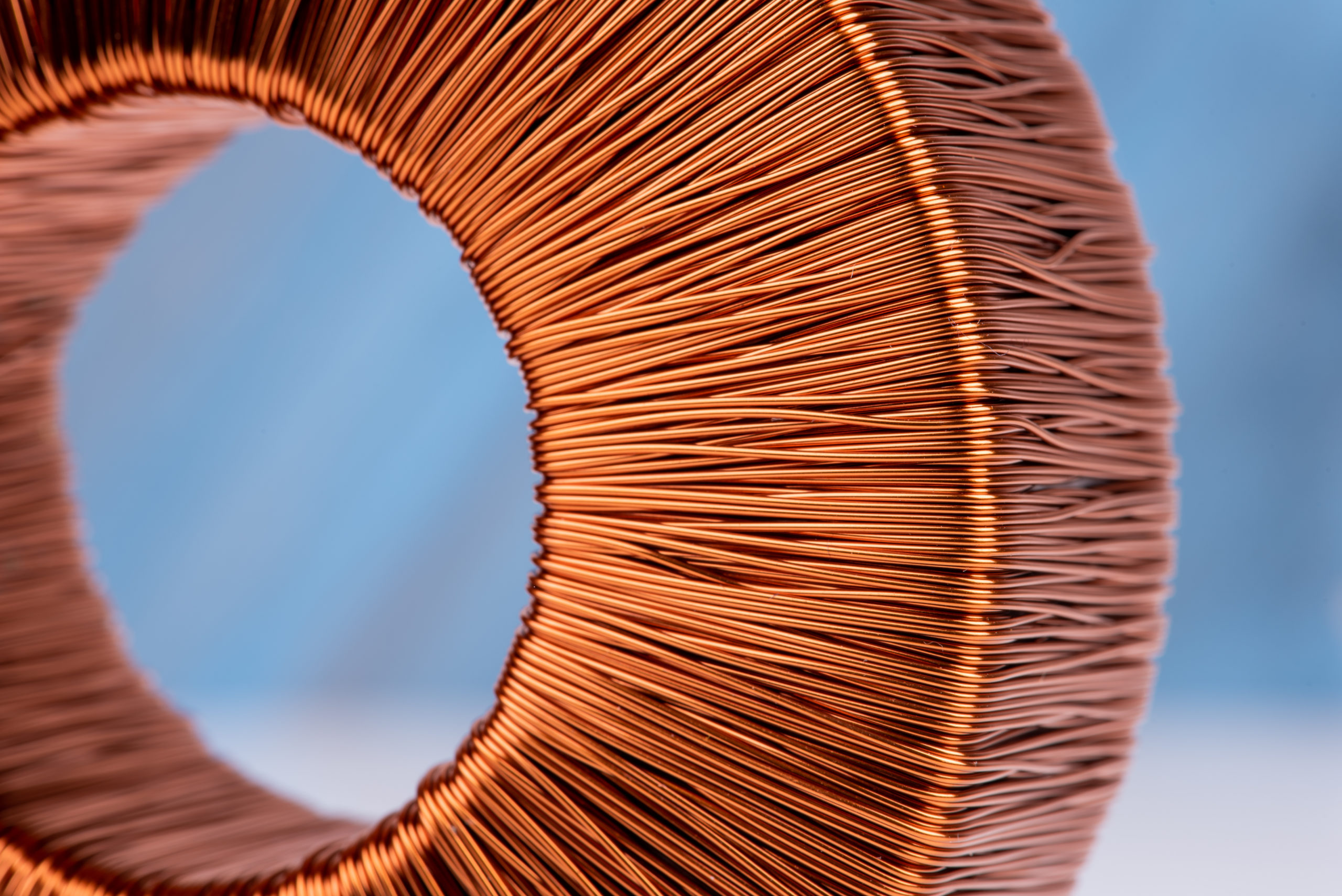

Copper:

Copper (Cu) is a soft, malleable, and ductile metal that has high electrical and heat conductivity with a reddish orange tint. Its ability to be easily shaped and formed makes it ideal metal for wire forming. Copper is resistant to rust and corrosion with a surface that forms a green layer when exposed to the atmosphere over a long period of time.

Aluminum:

Aluminum (Al) is a soft, non-magnetic, ductile metal and is the third most abundant metal on Earth. It is processed from bauxite and is found combined with over 270 other minerals. The main attributes of aluminum are its low density and corrosion resistance. To be used in the manufacture of wire forms, it has to be alloyed with other metals since in its natural processed state it is subject to deformation. The main alloying metals are copper, zinc, magnesium, manganese, and silicon.

Steel:

Steel is an alloy of iron with carbon added to improve its strength and resistance to fracturing. The main reason that steel is used in manufacturing is its tensile strength combined with low cost. The base metal of steel is iron. The interaction of the allotropes of iron with its alloys, mainly carbon, gives steel its properties. Since pure iron is very soft and ductile, the addition of carbon and other alloys improves its hardness, strength, and durability.

Stainless Steel 304:

Stainless steel grade 304 has high resistance to corrosion with a tensile strength of 621 MPa and can be used in conditions with mild corrosive elements or where handling of heavy loads is required. The quality of grade 304 makes it durable and long lasting. It can be used in conditions that have temperatures that exceed 1500° F but less than 2500° F.

Stainless Steel 316:

Grade 316 stainless steel has higher resistance to corrosion and can withstand the effects of chlorides. It has a tensile strength of 579 MPa and can handle extreme heavy loads. Grade 316 can be used in environments with temperatures that do not exceed 1400° F. Its ability to withstand caustic or highly corrosive environments has made it extremely useful.

Stainless Steel 434:

Stainless steel grade 434 is a ferritic alloy that is resistant to pitting and does not have any nickel content, which makes it less expensive. A restriction on stainless steel grade 434 are the temperatures at which it can be used, less than 1500° F, limiting its use for heat treatment applications. It is highly resistant to oxidation, corrosion, and pitting and is very useful in the production of industrial baskets.

CONTACT ACME WIRE PRODUCTS

Acme Wire Products has designed, recommended and manufactured custom wire components for customers in many diverse markets. We offer the benefit of our almost 50 years’ experience in the manufacture of component parts for hardware, medical & lab equipment, cable management, sporting goods, firearms, furniture, guarding, HVAC, pharmaceutical, automotive, optical and food service and processing industries.

Acme Wire’s designers work with our customers to create a wire component that will provide the greatest functional value. The design of wire products such as levers, handles, supports, rings, guards, baskets, trays, grids, frames, shelves are limited only by one’s imagination (and the limitations of technology).

Contact Acme Wire Products to assist you in determining the wire product best suited to your requirements!

Call Acme Wire Products at 1-800-723-7015 to get started.

Acme Wire Products Co., Inc. – Mystic, CT

Fax – 860-572-9456