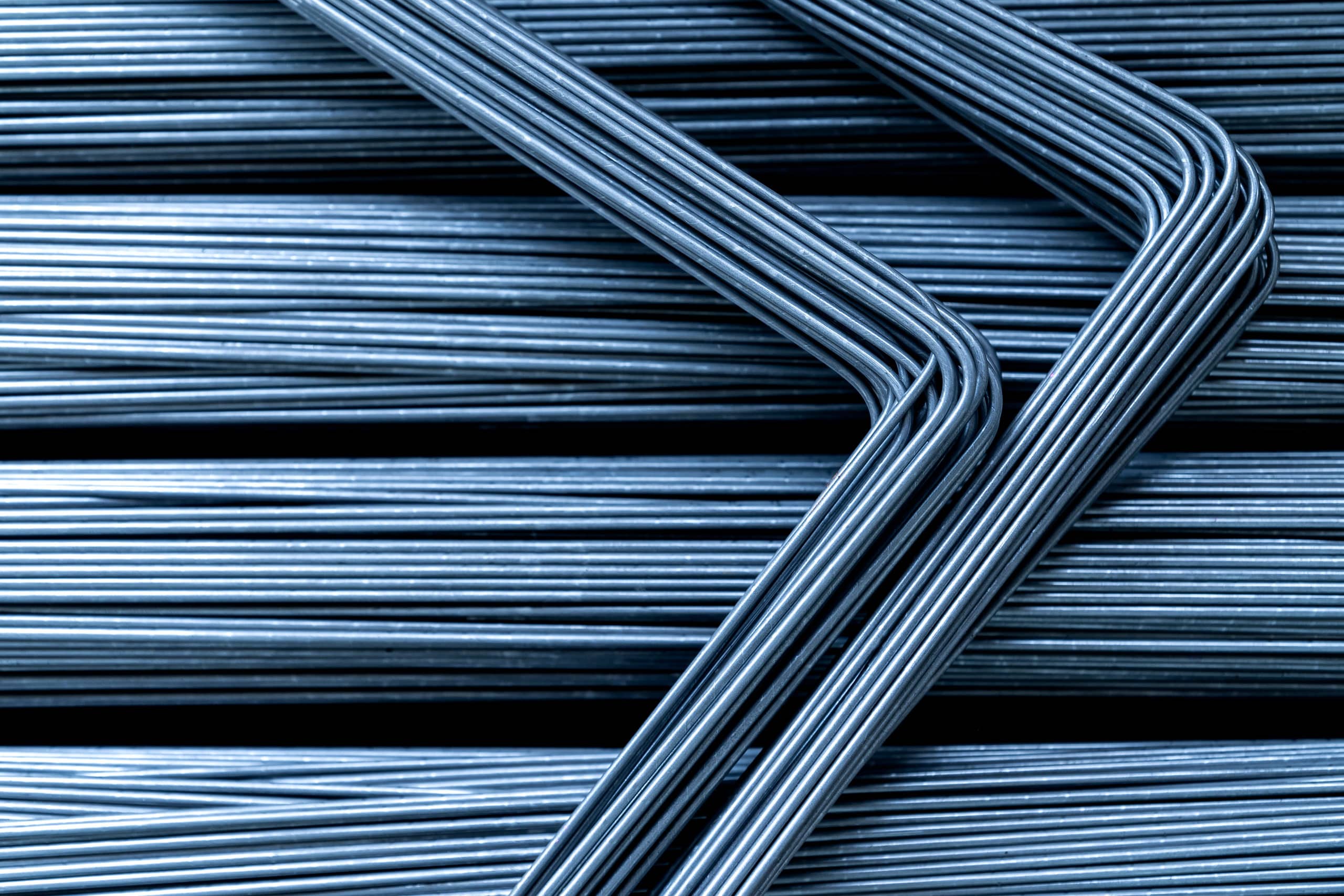

When it comes to the kind of materials used for wire forming projects there are several different options to choose from. However, knowing which materials are best to use, will depend on how the wire form is going to be used post formation. You might be wondering what exactly that means, well you could have two nearly-identical designs but they are made from different materials and are used in different conditions.

With this in mind, here’s a short list of some of the best materials to use for wire forming projects:

Grade 304 Stainless Steel

As an austenitic stainless steel alloy, grade 304 SS boasts an incredibly high resistance to corrosion. With a tensile strength of 621 MPa (90 ksi), this metal is stronger than either Grade 316 or Grade 317 SS—making it ideal for use in environments with mild corrosives and for handling heavier loads.

In most use environments, Grade 304 stainless can resist oxidation better than plain steel or iron. This helps any wire form made from 304 SS last longer without the need for replacement.

In high-temperature applications, Grade 304 SS is suited for use in processes up to 870°C (1,679°F). At temperatures of 1,399°C (2,550°F) or higher, the alloy will begin to melt. So, while the material can more than take most oven-like conditions, it isn’t really rated for the toughest heat treatment applications.

Grade 316 Stainless Steel

Another austenitic stainless steel, Grade 316 SS is even more resistant to corrosion than 304 SS. In particular, 316 stainless steel is better at resisting chlorides (like salt) and is often used in cookware and naval applications because of this fact.

The tensile strength of 316 SS is a little lower than 304’s, weighing in at 579 MPa (84 ksi). Not a major difference, but it can be important for applications with heavier-weight loads.

The maximum use temp of this alloy tops out at around 800°C (1472°F)—less than the use temp recommended for 304 steel.

Ultimately, Grade 316 SS is most useful for applications where 304 SS would normally be used, but the use conditions are too caustic or involve chlorides.

Grade 434 Stainless Steel

A ferritic alloy of stainless steel, Grade 434 SS is noted for having an exceptional resistance to pitting. Because 434 SS doesn’t have any nickel content, it is often less expensive than austenitic stainless steel.

The highest recommended use temperature of 434 SS is 815°C (1499°F), making it well-suited to the average high-temperature process, but still not ideal for heat treatment applications.

Although less chemically resistant than Grade 304 stainless, Grade 434 is still better at resisting oxidation, corrosion, and pitting than plain steel. This makes 434 a good general-purpose choice for making steel wire products—and at a lower cost than 304.

Grade 330 Stainless Steel

Grade 330 SS is another alloy specifically formulated for use in high-temperature applications. With its high chromium and nickel content, Grade 330 stainless can withstand prolonged exposure to temperatures of up to 1,037°C (1,900°F).

This makes it slightly less robust. However, it is also less costly to acquire and machine, so it is often recommended as an alternative to name-brand material.

These are just a few of the different materials that can be used to make (or coat) a wire form. The best one for your particular wire forming project depends on just what you plan on using it for, and the chemicals, temperatures, and processes involved.

CONTACT ACME WIRE PRODUCTS

Acme Wire Products has designed, recommended, and manufactured custom wire components for customers in many diverse markets. We offer the benefit of our almost 50 years of experience in the manufacture of component parts for hardware, medical & lab equipment, cable management, sporting goods, firearms, furniture, guarding, HVAC, pharmaceutical, automotive, optical, and food service, and processing industries.

Acme Wire’s designers work with our customers to create a wire component that will provide the greatest functional value. The design of wire products such as levers, handles, supports, rings, guards, baskets, trays, grids, frames, and shelves is limited only by one’s imagination (and the limitations of technology).

Contact Acme Wire Products to assist you in determining the wire product best suited to your requirements! Call Acme Wire Products at 1-800-723-7015 to get started.

Acme Wire Products Co., Inc. – Mystic, CT

Fax – 860-572-9456